Reports available from the telematics management system include: fleet status; machine location (last reported GPS location); operating hours; fuel usage; fuel and diesel exhaust fluid (DEF) levels; engine idle time versus work time; error codes; engine and hydraulic oil temperatures; load counts and weights; and tonnage hauled.

Doosan Infracore North America LLC introduced DoosanCONNECT — a new telematics management system for Doosan excavators, wheel loaders, material handlers, log loaders and articulated dump trucks. The connected machine solution provides greater machine-to-machine communication, machine intelligence and remote equipment monitoring to maximize machine uptime protection, according to the manufacturer.

Since 2008, Doosan has offered a telematics management system to its customers. The new DoosanCONNECT telematics system is standard on all Doosan equipment, except DX63-3 and DX85R-3 compact excavators. Each new machine comes with a free 36-month subscription. Customers have the option to purchase a service extension after the subscription expires, and the subscription is transferrable if a customer sells a machine to another individual.

How it Works

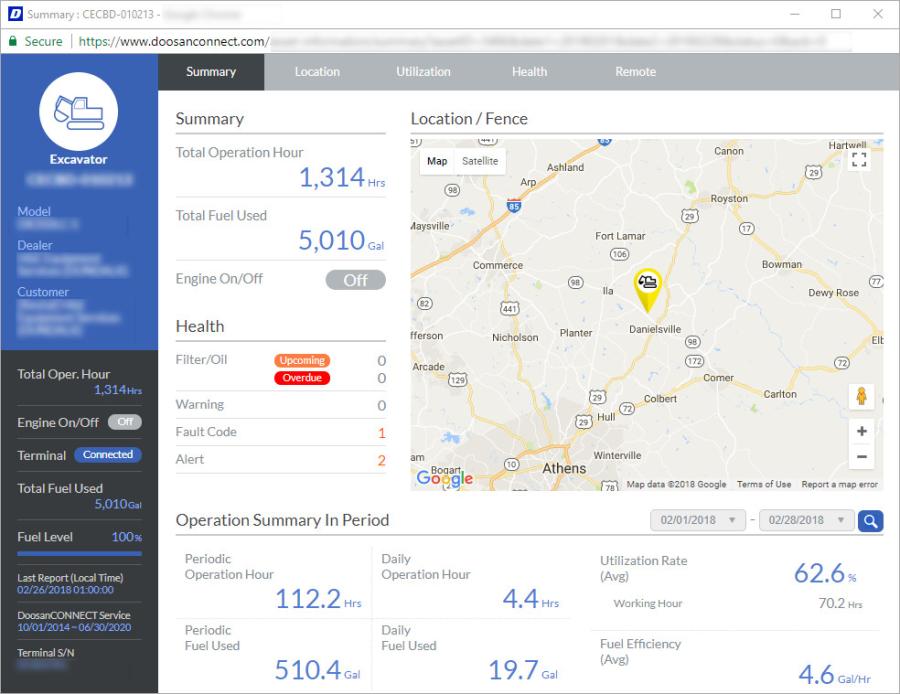

Doosan equipment is equipped with a modem, furnished with a cellular and satellite antenna, which collects data from sensors on the machine. The modem sends the data from the machine to a central database via cellular or satellites, making it readily accessible, even in remote locations when cellular service is not available. Equipment owners and fleet managers can review the data produced and monitor the equipment remotely from an internet-enabled device by logging into the DoosanCONNECT website: DoosanCONNECT.com.

The website is available in 11 different languages and viewers can choose their preferred language from a drop-down menu. A mobile app is available for download from DoosanCONNECT.com to allow owners to access DoosanCONNECT alerts from a connected mobile device.

Below is a sample of the many reports available from the telematics management system:

- Fleet status

- Machine location (last reported GPS location)

- Operating hours

- Fuel usage

- Fuel and diesel exhaust fluid (DEF) levels

- Engine idle time versus work time

- Error codes

- Engine and hydraulic oil temperatures

- Load counts and weights

- Tonnage hauled

Better Manage Equipment

DoosanCONNECT puts more information in the hands of equipment owners to help better manage their equipment fleet. They can monitor operational utilization reports to determine how often their Doosan equipment is being operated. An operation trend report includes a search by time period option, average utilization rate, and load count and weight data. By analyzing this data, Doosan equipment owners can determine if they are underusing their assets or whether it is time to invest in adding to their equipment fleet to maximize their return on investment.

Data collected through DoosanCONNECT can also be used to solve business challenges, such as improper use of equipment on the jobsite. Owners can use this data to correct operator behavior to promote a productive and safer job site.

The connected machine solution displays operation hours. Accurate machine usage reports can help owners fine tune their bids and determine operating costs and labor costs for more accurate billing on future jobs.

Track Fuel Usage

With the help of DoosanCONNECT, owners can make improvements to equipment fuel efficiency and reduce diesel fuel consumption. Fuel efficiency (gallons per hour) and fuel used (gallons) can be viewed from the website, eliminating the need to physically check each machine and minimizing trips for a fuel truck.

The system also monitors equipment idle time, helping to identify machines that are working under or over capacity. Reducing idle times can help extend engine life and reduce repair and maintenance costs. Owners also can monitor power mode operation and advise operators to adjust the power mode to do the same work while using less fuel.

Warning Information Readily Available

DoosanCONNECT enables equipment owners to track service and maintenance warnings. The website provides owners with a fault code status and history related to the machine's engine, transmission, steering and more. Maintenance warnings alert owners and fleet managers with an easy-to-read status of a machine's parts status. A list of parts includes each part's status — good, upcoming or overdue — and the number of hours used. Dealers also can monitor this information and proactively reach out to customers to encourage them to properly service their Doosan equipment to ensure the machine is operating correctly.

Improved Maintenance Scheduling

Integrating DoosanCONNECT into a maintenance management program allows equipment owners to look ahead and see when a machine is due for its next maintenance appointment. If a problem does arise, DoosanCONNECT reports real-time fault and warning codes. The data can be shared with dealers, enabling a quick response and ensuring more uptime and continued productivity. Dealers can view the problem on the DoosanCONNECT website to help diagnose the problem without physically being in the same location as the machine. This helps save unnecessary downtime and reduces travel time for the dealership's service department.

Reduce Equipment Theft

Equipment location is an important data point for equipment owners. Using DoosanCONNECT, equipment owners can view the equipment's last reported GPS location, including an aerial map view. This feature allows them to keep a close eye on their equipment fleet and see where its being operated through the DoosanCONNECT website.

Customers can create a geo/time fence or an invisible/virtual boundary through the machine's GPS system. If the machine leaves the virtual fence, it will send a notification and can alert the equipment owner and authorities about possible equipment theft. Additionally, a time fence or curfew on each machine can be created. If the machine is operated outside of working hours, an email or SMS text notification can be sent to the owner. This helps to prevent unauthorized operation and potential vandalism to the machine and job site.

For more information, visit DoosanEquipment.com.

Today's top stories