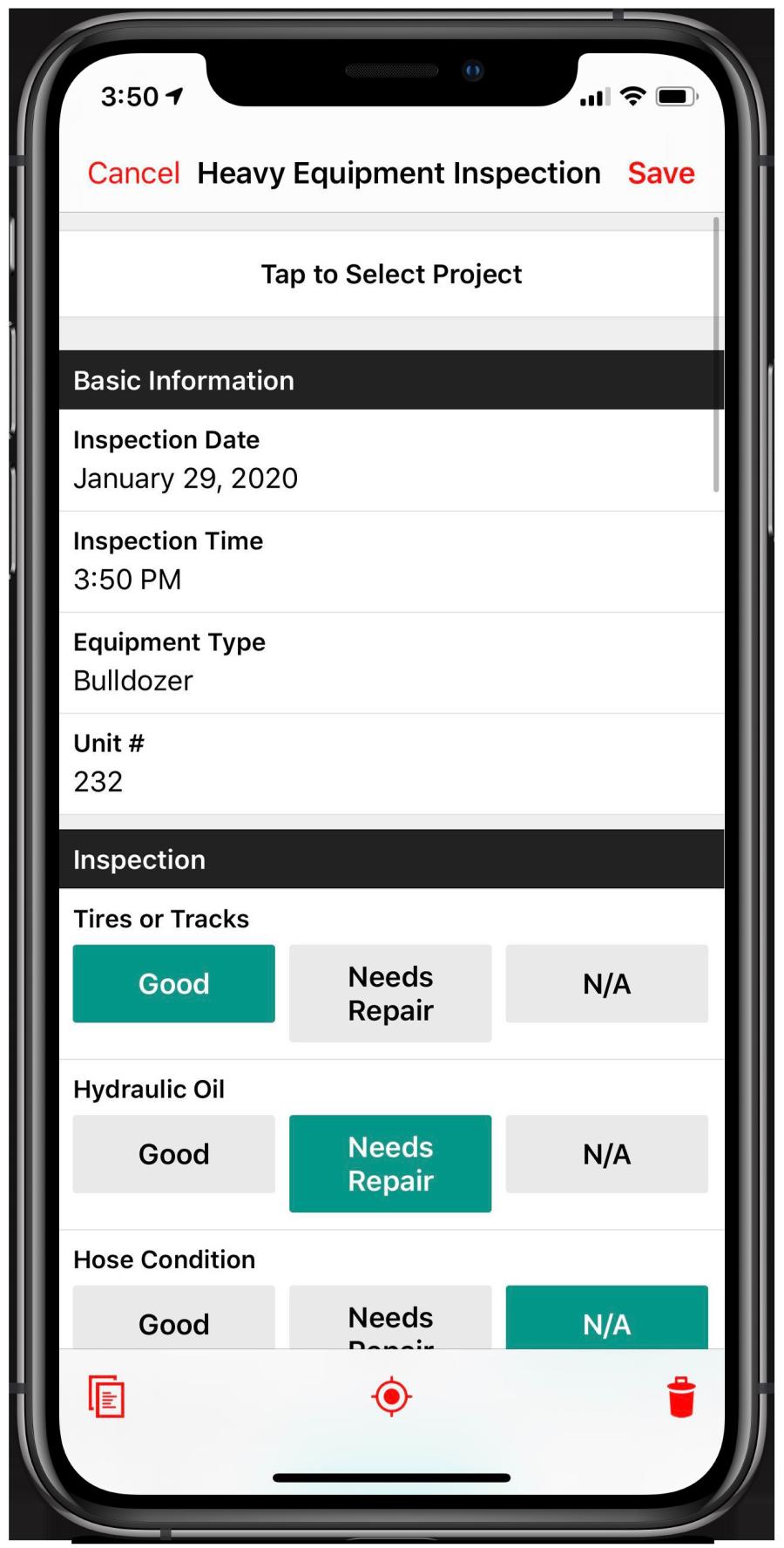

Many equipment fleet managers are integrating software apps in conducting machine inspections to avoid the operator or equipment technician having to drag a laptop and camera to the equipment.

(Snappii photo)

Ever more stringent government regulations that demand concise and accurate documentation of heavy equipment performance are making equipment inspections even more critical. Though pencil and paper are still tools-of-choice for many in the shop and the field, the construction equipment sector is rapidly adopting the use of apps via tablet, portable electronics and even cellphone, for the sake of efficiency.

Logging inspection data by hand is time-consuming, and the paper trail can bog down fleet management operations. Toronto, Ontario, Canada-based inspection software developer Field Eagle notes that manually re-entering field data in the office is a drain on resources and can result in errors that actually invalidate the whole inspection.

"Another issue is that paper forms are simply harder to keep current and updated with changing government and municipal regulations," noted a Field Eagle blog post. "Electronic forms on laptops, tablets and smartphones are a much more productive way forward."

In fact, once they're implemented, cloud-based equipment inspection systems offer lower overhead costs and streamline the documentation process, said Coleman McCormick, vice president of product of Spatial Networks Inc., St. Petersburg, Fla., which developed the Fulcrum app. Fulcrum allows the user to capture detailed inspections of construction equipment. Like other apps, the customizable form also can be used to track routine maintenance requirements and defects.

An Argument for Apps

"Cloud-based systems are lowering overhead and CapEx expenditure for IT systems — a trend that began in earnest in the early 2010s and has exploded in recent years," said McCormick. "‘Bring-your-own-device' types of deployments are becoming commonplace, making the access to mobile apps for business workflows easier, and lowering the cost of adoption for IT departments," because, he added, they no longer need to buy or maintain hundreds of smartphones.

Birmingham, Ala.-based fleet management software developer Fleetio believes electronic inspection technology empowers heavy equipment operators to perform faster, more thorough inspections. With a mobile app, operators can upload photos of machine issues and make comments for a more thorough diagnosis. Fleet managers, in turn, receive notifications about vehicle issues instantly to help jumpstart the maintenance process.

Further, digital inspections ensure fleet compliance with federal regulations. All information from electronic vehicle inspections is automatically uploaded in the fleet management app. Having an organized system of recordkeeping saves hours of manual data entry and eliminates any concern over misplaced or damaged forms.

Heavy equipment inspection apps also improve operator integrity, believes Fleetio. The company's software program automatically tracks the GPS location of each inspection, ensuring operators are performing inspections in the proper locations. Monitoring inspection location can alert management to questionable data submissions. Concerned about whether inspections are being performed at the proper time and place? Consider adjusting proximity thresholds to further monitor completions, suggested Fleetio.

What Customers Want

With apps such as Fulcrum, users can create custom apps with Web-based drag-and-drop features, then deploy those apps to remote users to complete on their mobile devices, said Spatial Networks' McCormick. "Once inspection data is collected and synced to the Fulcrum server, users can access records — which are all geo-tagged — from either the mobile device or web platform."

Customers like these digitized systems because they feature offline support so users can work in disconnected settings. That ensures the resiliency necessary to keep working even when the user goes out of cellular coverage, said McCormick. They also offer flexibility so users can design forms to their organization's specific workflow needs. And, they're simple.

"Their easy-to-use mobile interface makes data entry as smooth as possible and requires limited training to get an inspector up and running with the app," he said.

Alexandra Murashova, in marketing support for heavy equipment app developer Snappii, in Durham, N.H., said customers are specifically looking for inspection apps that offer features for logging machine maintenance, equipment location and fleet inventory. She said users like to "conduct detailed inspections covering each major systems and components of heavy equipment" and want to be able to "indicate problems, disrepairs and malfunctions in the equipment performance; manage heavy equipment inventory by scanning bar codes; and create and quickly share PDF/Excel reports with the team."

She believes the benefits of using apps such as Snappii can be seen in time savings in data collection, money savings on document processing — customers like the fact that "fees to store paper and retype information" are eliminated — and improved team communication.

"They also want a chat feature to be able to quickly talk to each other about projects," she said.

These apps are specifically designed for technicians, operators and designated inspectors to conduct heavy equipment inspections without having to drag a laptop and camera into the shop or out to the field. Some will instantly enable equipment inspections with any mobile device, and once the inspection is completed, can sync data among many devices or distribute it from one device to the team via e-mail.

According to a Snappii blog post, equipment maintenance costs can drop by 25 percent simply by implementing an inspection app. With itemized checklists for daily, monthly or quarterly inspections at-hand, a heavy-equipment inspection app can help legally protect companies by converting the data to reports and providing information when it's needed.

App Specifying Considerations

Field Eagle notes one big question many users have when they start shopping for an app is whether a smartphone is as useful as a tablet for conducting and logging heavy equipment inspections. The answer, believes the Canadian software developer, depends on the complexity of the inspection being performed.

"If there are a limited number of items being inspected, a smartphone might be suitable. It is important to understand and consider the smaller screen size. Limited screen real estate can impact efficiency," stated the Field Eagle blog. "At the other extreme is a laptop device. Unfortunately, laptops are not as easy to use in the field and, in most cases, are not as rugged."

A happy medium between these two, suggests the company, might be the tablet.

"It offers the best of both options, with a touch-screen interface and smart pen support. Tablets can bridge the gap for inspectors."

Here is a list of other features Field Eagle suggests end users consider when specifying the tools a technician will need to conduct and archive heavy equipment inspections:

- Rugged versus non-rugged hardware: ‘Rugged' implies a device that can take rough handling in the field and on-the-job accidents. The choice depends on the locations being inspected and the overall environment. Consider the temperature as well as the area in general: Cold climates by themselves do not warrant a rugged solution, suggests the blog entry.

- Overall cost: Rugged tablets are generally more expensive than their non-rugged counterparts. There are several reasons to consider rugged solutions from an IT management perspective, however:

- Battery life: Rugged units are generally designed with longer-lasting batteries because it's assumed they'll be used in areas with limited power options. With long-life batteries, inspectors can work longer without having to worry about power issues in the field.

- Standardization: Because rugged devices have a longer production cycle, accessories such as chargers and docks can be standardized across the fleet. Using a single device type, IT support is generally easier and hot standbys can be stored for easy replacement.

- Customization: Though standard in type, rugged devices can actually be customized as a solution so that they better meet your requirements. This includes the addition of separate cameras, scanners, and RFID options.

- Lower ownership costs: While upfront costs for rugged devices are often higher, in the long run they are cost-effective when generally used for three to five years. In addition to the actual device cost, total cost of ownership also must include lost employee productivity, due to the failure of a non-rugged device.

- Operating system: Choosing the right platform boils down to cost and capabilities. Rugged tablets are designed to perform a specific function, so they often have custom software that communicates with the user's internal network. Based on the software created and the language used, alternative options are available. Generally speaking, Android tablets are the most cost-effective, according to Field Eagle. However, because there are various levels of quality with Android, care must be taken to ensure the components used are of high quality.

- Tablet capabilities: Both commercial and rugged tablets share some similarities, such as the specifications that they are measured on. Look at speed of the processor, quality of the camera, quality and resolution of the screen, Bluetooth capabilities to allow pairing with input devices, touchscreen capabilities, amount of memory, overall screen size and weight. These factors all affect overall price and field performance.

- Internet access: Inspections are often conducted in remote locations or places with limited data access and connectivity. Uploading files and data in real-time is simply not a possibility. If the inspections require a significant amount of video or photographic evidence, it is important to ensure that the device has sufficient memory.

Beyond the fact that regular inspections of heavy equipment are required practice, a well-managed inspection policy can improve a company's assets and earning potential. Performing a thorough daily walk-around, an operator can detect any machine issues and then communicate them to a fleet manager. Though many construction equipment companies still use paper inspection forms to manage their assets, cloud-based software apps are winning favor with users for efficiency, accuracy, and safety. CEG

Lucy Perry

Lucy Perry has 30 years of experience covering the U.S. construction industry. She has served as Editor of paving and lifting magazines, and has created content for many national and international construction trade publications. A native of Baton Rouge, Louisiana, she has a Journalism degree from Louisiana State University, and is an avid fan of all LSU sports. She resides in Kansas City, Missouri, with her husband, who has turned her into a major fan of the NFL Kansas City Chiefs. When she's not chasing after Lucy, their dachshund, Lucy likes to create mixed-media art.

Read more from Lucy Perry here.

Today's top stories